Service hotline

+86 18518316054

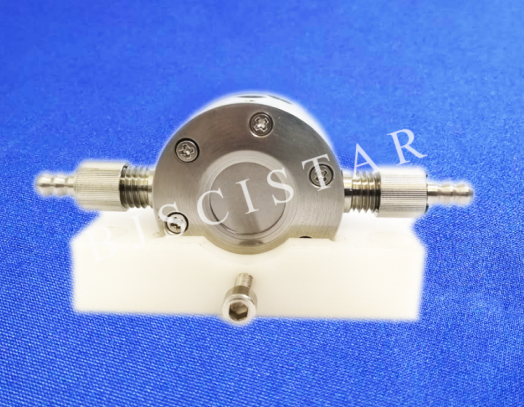

The LA-TXAS cell is one type of in-situ Lithium-air-battery cells for X-ray absorption spectroscopy characterization. The in-situ cell is mainly applied in the fields of lithium air reaction systems, which collecting the Synchrotron radiation X-ray absorption spectra of the catalysts in real time. The cell can help researchers make a direct observation of the geometrical and electronic structural evolution on the catalysts. This is significant to reveal their related kinetic mechanisms and establish a connection between their structure/composition and the corresponding electrochemical performance.

Main features

1. The in-situ cell is designed for in-situ X-ray absorption spectra testing, which is based on the basic principle of lithium-air batteries;

2. Synchrotron radiation X-ray absorption spectrum data (transmission mode) or X-ray diffraction spectrum data (transmission mode) can be monitored in real time during the electrochemical process of the in-situ cell;

3. The in-situ cell, which equipped with four high purity Be windows, can make sure a higher X-ray transmittance (>=50%) at 7 keV with the Li metal and LiCoO2 materials;

4. One of the Be window is dealt with tens of holes for gas circulation;

5. The in-situ cell is equipped with two gas junctions on the main part to facilitate the control of the atmosphere during the experiment;

6. According to user needs, the gas junctions can be shut down or opened at any time for both of inlet and outlet sides;

7. The cell has a high-precision 18 mm diameter sandwich geometry, the electrode concentricity can be reach <0.1 mm;

8. Fluorine gaskets are used to seal all the cell, making sure the overall system sealing;

9. In the assembly process, the electrode materials and electrolyte can be easily assembled; meanwhile, all components can also be easily disassembled and cleaned.

10. The in-situ cell can be reused.

Optional accessories: high purity beryllium window (>= 99.93%); Kapton membrane; and Al foil.

Patent number:ZL2018 2 0287271.3