Service hotline

+86 18518316054

Current location : Home page > Products > Photocatalytic systems > CEL-PAEM-D8 photocatalytic activity evaluation system

Current location : Home page > Products > Photocatalytic systems > CEL-PAEM-D8 photocatalytic activity evaluation system

Model:CEL-PAEM-D8

Place of Origin:Beijing

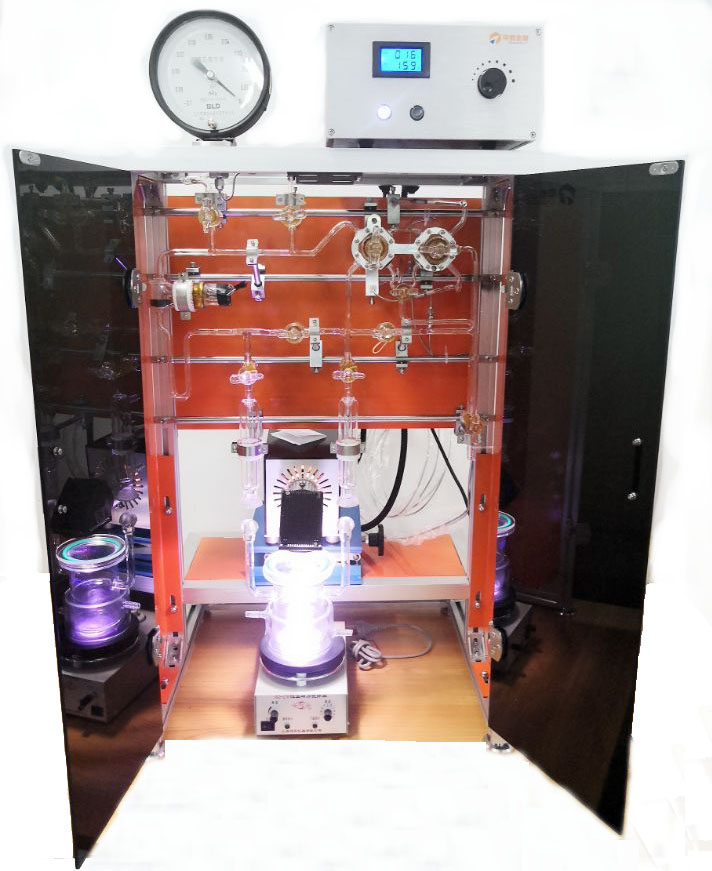

The CEL-PAEM-D8 photocatalytic activity evaluation system upgrades the original conventional photocatalytic water system, and integrates the glass system into a closed shading box, which is easy to move and not easy to damage. It is suitable for experiments with low hydrogen production and high catalyst cost, which is more conducive to the verification of the concept of total hydrolysate. Realize online automatic unattended test and analysis; Manual and automatic sampling can be selected.

Functional features and applications:

1. Trace reaction system, very low amount of catalyst;

2. Activity evaluation of semiconductor materials (TiO2, C3N4, CdS, etc.) catalysts

3. Performance analysis of hydrogen and oxygen production of catalyst

4. Performance analysis of catalyst carbon dioxide reduction

5. Can be equipped with photoelectric reaction, gas-solid reaction, membrane catalysis and other special experimental requirements * closed integrated design, panel using translucent plexiglass plate, all closed plate can be removed at any time for easy maintenance;

6. Online automatic unattended test and analysis;

7. Manual and automatic sampling mode can be selected (temperature control 200℃);

8. Easy and fast installation, compatible with any manufacturer of gas chromatograph;

9. Wide test range, hydrogen, oxygen, CO2, methane, CO, formaldehyde and other trace gases;

Technical parameters:

1. Pipelines are all made of glass, using patented glass valve for sampling, and 1.8L/s corrosion resistant fan for pipeline gas circulation;

2. Reactor volume: 25ml, 50ml, 100ml, 250ml;

3. Pipeline volume 50ml±5, vacuum degree -0.1MPa(72h dynamic);

4. Sampling mode: manual, automatic (automatic sampling valve fully wrapped temperature control, <200℃);

5. Control mode: software automatic control (8 bits); Automatic execution status, real-time display, software interface; USB and RJ45;

6. Test accuracy, 0.01ml& 0.01min;

7. Vacuum pump, reverse control automatic start and stop, 2L/s, including anti-suction solenoid valve;

The light source is still placed on the platform at the back end of the system, which is more stable and easy to replace the reactor and take and place samples;

9. Test range: hydrogen, oxygen, CO2, methane, CO, formaldehyde, acetaldehyde and other trace gases, H2, O2 >0.001ml; CO, CO2, CH4>1ppm; CH3OH, HCOOH, CH3CH2OH, CH3COOH>10ppm;

10. Glass gas path built-in U type cold trap pipeline, used to improve the vacuum degree and separation of volatile solvent;

11. Closed design, all the closed plate can be taken out at any time to facilitate maintenance of the glass system, the panel is made of translucent organic glass plate can observe the situation in real time, and can prevent light pollution, 560mm (wide) *470mm (deep) *860mm (high).

Recommended facilities:

Gas Chromatography GC7920

CEL-GSOA-20/V online double six-way sampling system, can cooperate with Shimadzu, Agilent to achieve automatic GC sampling