Service hotline

+86 18518316054

Current location : Home page > Products > Photocatalytic systems > CEL-SPH2N-D SLR series photocatalytic activity evaluation system

Current location : Home page > Products > Photocatalytic systems > CEL-SPH2N-D SLR series photocatalytic activity evaluation system

Model:CEL-SPH2N-D

Place of Origin:Beijing

Product application:

It can be used for hydrogen production by photohydrolysis of water, oxygen production by photohydrolysis of water and CO2 photocatalytic reduction at room temperature and pressure.

Advantages and features:

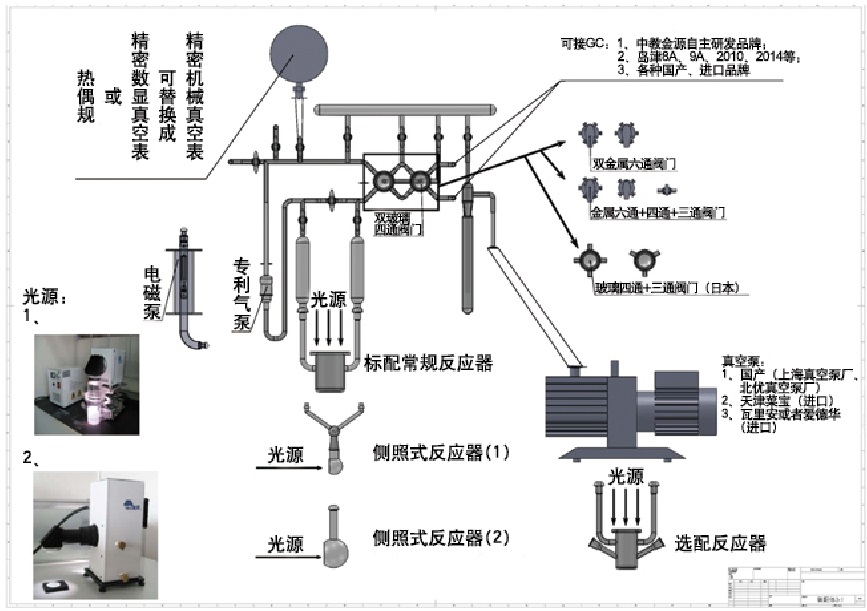

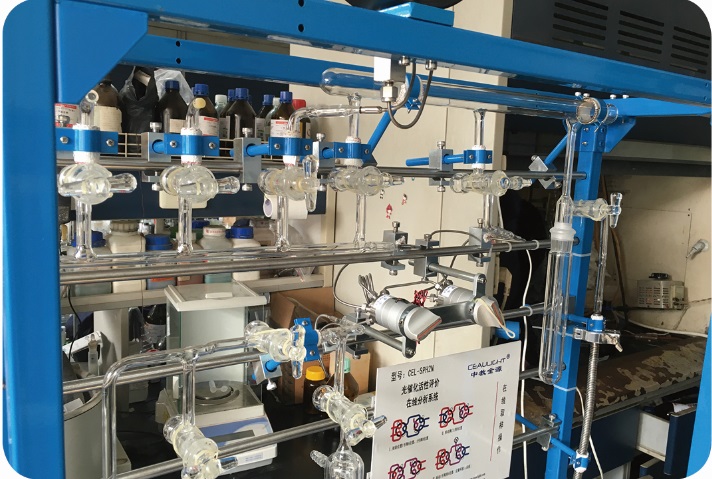

CEL-SPH2N-D SLR series photocatalytic activity evaluation system (also known as SLR water hydrogen production system) adopts a variety of valve combinations to collect and analyze samples (in line with national standard GB/T26915-2011), which can carry out experiments such as photocatalytic hydrogen production from water, photocatalytic oxygen production from water and photocatalytic reduction of CO2 at room temperature and pressure. . Functional applications: qualitative and quantitative products, and light quantum efficiency testing.

Specifications and parameters:

DSLR series photocatalytic activity evaluation system:

mname | model | instructions | Recommend index |

Photocatalytic activity evaluation system | CEL-SPH2N-D1 | Basic model with metal (6+4+3) valve injection system | ★★ |

Photocatalytic activity evaluation system | CEL-SPH2N-D2 | Equipped with glass (6+6) valve sampling system, it is difficult to process, easy to damage and high maintenance cost | ★ |

Photocatalytic activity evaluation system | CEL-SPH2N-D3 | Equipped with glass (4+3) valve injection system, complete reference to Japanese equipment injection system | ★★ |

Photocatalytic activity evaluation system | CEL-SPH2N-D5 | Equipped with glass (4+4) valve injection system, | ★★★★ |

Photocatalytic activity evaluation system | CEL-SPH2N-D7 | Equipped with metal (6+6) valve sampling system to realize automatic data acquisition. | ★★★★ |

Automatic photocatalytic activity evaluation system | CEL-SPH2N-D9 | Automatic, equipped with automatic sampling system, arbitrarily defined time interval, unwatched, automatic data acquisition, automatic analysis and storage | ★★★★★ |

Optional: Light source: CEL-HX series xenon lamp light source, CEL-LED100LED high-power light source, CEL-S simulated solar xenon lamp; Gas chromatography :GC-7920 series, GC7900 series, Shimazu, Agilent; Power meter: CEL-NP2000 series, imported Newport, used for quantum efficiency measurement; Filter: Referring to the relevant information of the filter, nearly a thousand kinds of filters are available; Cooling circulating water machine: recommended long flow LX series, or imported products. | |||

DSLR series photocatalytic activity evaluation system technical parameters:

1) Vacuum degree: relative vacuum degree -0.1Mpa (over 72 hours, dynamic test); Absolute vacuum <3× 10-4MPa (PV= NRT)

2) Fully automatic control valve, fully automatic control software, sampling time and sampling times can be set arbitrarily, the system is completely computer controlled, without tedious valve operation;

3) Glass high vacuum system circulation pipeline with patent technology

4) High efficiency circulating pump, instant mixing in 1s seconds, no need to wait, sampling at any time, mixing speed 1.8L/min;

5) Used for trace gas reaction and product detection, the volume of the system circulation pipeline is less than 150mL;

6) Vacuum characterization: relative pressure precision vacuum gauge, precision 0.4 grade (intuitive); Relative pressure digital vacuum meter optional); Absolute pressure digital display vacuum gauge, accuracy 0.1Pa(optional);

7) The hydrogen production test range is wide: 0.1 microliter ~100 ml (expandable 1000ml), precision PPM level;

8) Linear regression degree of standard curve: K>0.9999(all actual measurements were 1);

9) Standard multi-function buffer gas storage device, can be connected to the standby gas tank;

Quantitative sampling,

10) 0.5 ml / 1 ml / 1.5 ml / 2.2 ml / 3 ml optional, repeated sampling error, avoid wrong operation;

11) National standard eight-way valve, seven-way valve, six-way valve, four-way valve, three-way valve, two-way valve and the combination of the above valves can be selected according to the user's habits, the material can choose corrosion resistant stainless steel, glass, control can choose manual, semi-automatic, automatic;

12) The sampling part of the DSLR system has no dead volume and no gas series jamming phenomenon;

13) Standard reactor with double layer constant temperature water jacket (250ml/100ml/50ml optional), pressure resistant full spectrum hyperpermeability quartz window;

14) Condensation system: double layer cooling device (spherical cooling or direct cooling is optional);

15) Built-in gas protection function, can ensure the gas chromatography GC safety under misoperation (such as insufficient carrier gas pressure);

16) 2 sets of standard injectors (including gas injection needles);

17) The light source equipment is placed behind the system, and the reactor is installed and disassembled without moving the light source;

18) Adopt stainless steel bellows KF16,1.8m, no vibration, clean, no pollution, can be arbitrarily bent, standard multi-purpose interface, can be connected with various vacuum pumps.

19) Vacuum pump: vacuum pump of domestic or imported brands, with anti-oil suction function, pumping rate of 2L/s;

20) Double layer high stable support platform is adopted to ensure the safety of the glass instrument; Integrated design, including movable universal wheel for easy movement.

21) On-site installation and debugging, training, experiment, maintenance-free.

22) The system covers a small area, does not occupy the test bench, independent integration, to solve the tension of the existing test bench.