Service hotline

+86 18518316054

Current location : Home page > Products > Electrodes > High temperature and high pressure reference electrode

Current location : Home page > Products > Electrodes > High temperature and high pressure reference electrode

Model:Not yet

Place of Origin:Not yet

High temperature and high pressure reference electrode:

1.Adopt the patented product queon® material for sealing to ensure the integrity and safety of sealing under high temperature and high pressure conditions

2. Adopt one-piece structure, no need to assemble by customer

3. Long time continuous use, no leakage of salt bridge solution

Technical indexes.

1. Working temperature: 0-220℃ Optional 310℃

2. Working pressure: 0-2000psi (13.7MPa)

3. Sensitive element: Ag/AgCl

4. Measurement range: -2500mV - +2500mV

5. Accuracy: ±5 mV

6. Impedance at room temperature: <9 kohm (kΩ)

7. KCl solution permeation rate: 1µL/week

8. Material of tube body and mounting parts: 316L

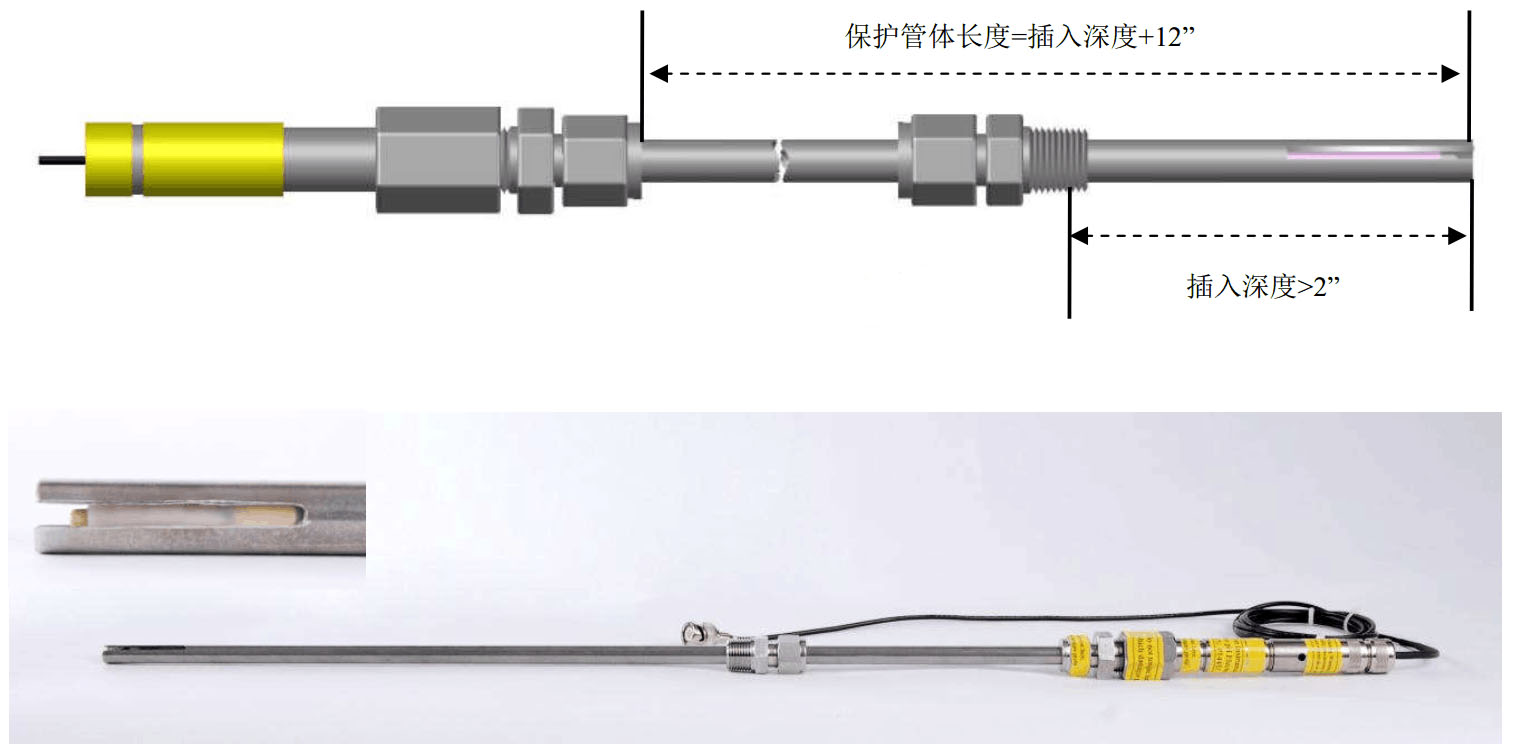

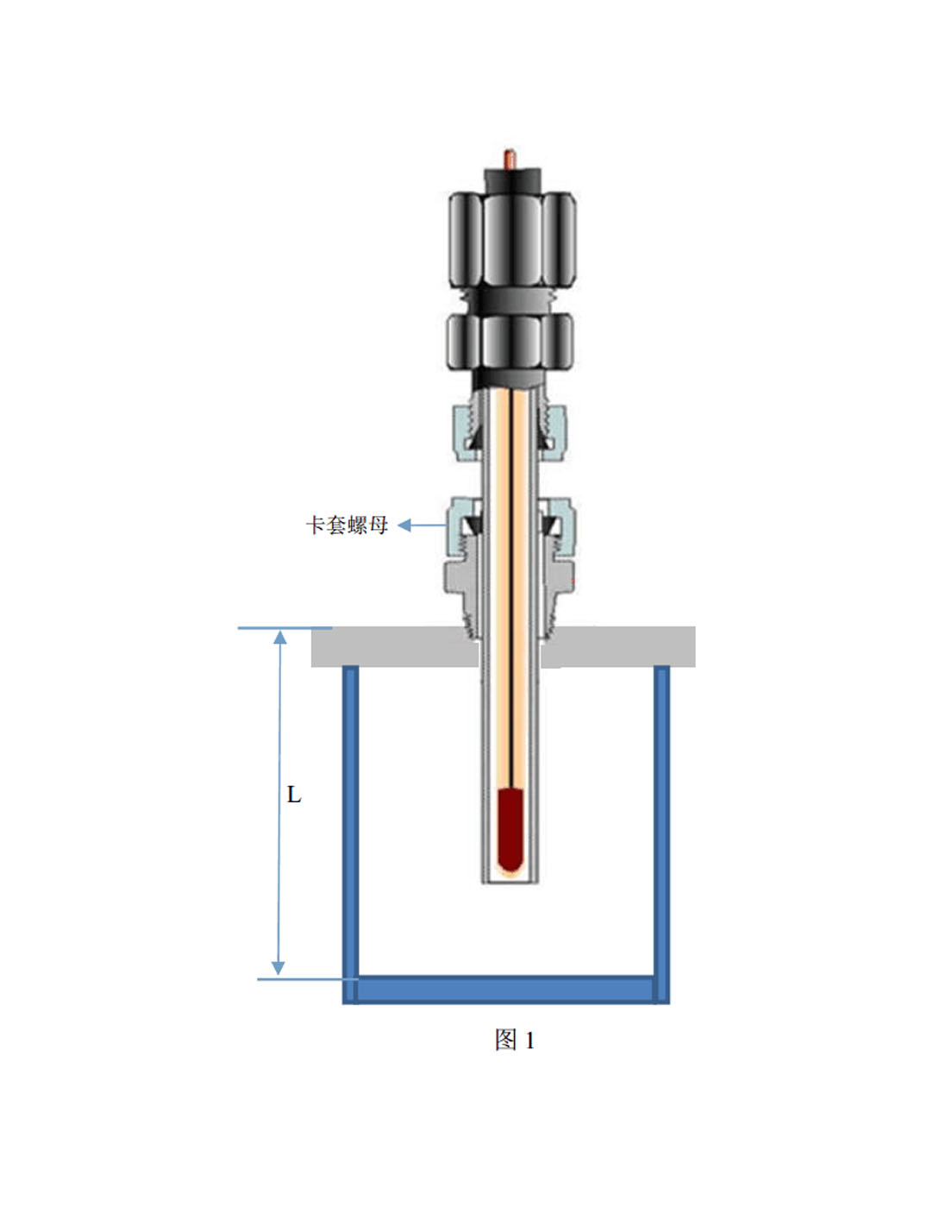

9. Insertion depth: >2" (5cm)

Note: The insertion depth is determined at the first installation and cannot be changed thereafter.

Precautions for use.

1. Extra care must be taken during system ramp-up/down. Electrodes or electrode sensitive components can cause personal injury or death due to improper handling, excessive pressure or other reasons, resulting in electrode components as if they were projectiles. Operators should avoid being around the system during system ramp-up/down and use electrodes in a controlled or enclosed environment where possible.

2. Do not rotate the electrode components (as shown), any rotation of these components will affect the safety and integrity of the electrode and may also damage the electrode and void the warranty.

3. The rate of pressure rise and fall of the system should be slow. Especially in the presence of CO2 or other gases in the system, the ramp-up/down rate should be less than 200psi/hr and sharp pressure changes must be avoided to prevent damage to the electrodes*. (* In systems with high partial pressures of gases (e.g. CO2, N2, H2), large amounts of gas can diffuse into the internal element of the reference electrode and dissolve in the KCL solution. The gas in the internal element does not change the electrode potential of the reference electrode, but when the pressure is suddenly reduced, the gas can mechanically damage the internal element of the electrode. When the external environment is suddenly depressurized (e.g., from 400 psi to 200 psi, or from 200 psi to 0 psi), the large amount of gas dissolved in the internal element becomes high pressure gas and cannot diffuse out quickly. (A large pressure difference in a short period of time can cause the internal element to expand or fail.

4. Do not operate the electrode under conditions exceeding the rated temperature or pressure, as this will damage or shorten the life of the electrode.

5. The patented design can effectively prevent air bubbles from forming at the liquid connection. If the electrode is inverted, air bubbles may form at the liquid connection, resulting in unstable measurement. If this situation occurs, hold the electrode vertical and gently tap or shake it against the electrode tip to remove the air bubbles.

Use and calibration of reference electrode.

1. Usually the reference electrode has been calibrated at the factory. Users can calibrate the reference electrode with the standard hydrogen electrode at room temperature if they need to do so in the later use process.

2. Before each experiment, compare the electrode potential between the reference electrode and normal reference electrode at room temperature and pressure; after the experiment is finished, compare the electrode potential between the reference electrode and normal reference electrode again at room temperature and pressure, if the drift of the electrode potential before and after the experiment does not exceed 5mV, the reference electrode is normal.

3. The annual drift of the electrode potential of the reference electrode is between 30~50mV as the normal condition.

4. If the electrode potential of the reference electrode suddenly decreases, it means there is a problem with the electrode.

Prev:No more!