Service hotline

+86 18518316054

Current location : Home page > Products > Solar cell IV,QE/IPCE > CEL-QPCE2050 Dye Sensitized Solar Cell Spectral Response System (QE/IPCE)

Current location : Home page > Products > Solar cell IV,QE/IPCE > CEL-QPCE2050 Dye Sensitized Solar Cell Spectral Response System (QE/IPCE)

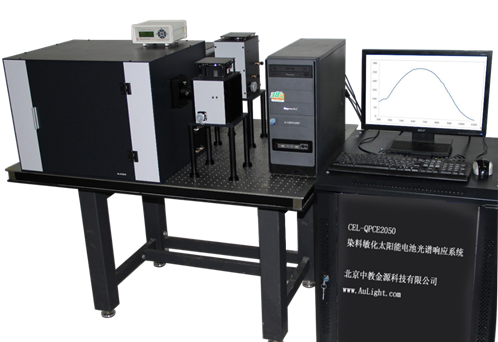

Model:CEL-QPCE2050

Place of Origin:Beijing

Working Principle:

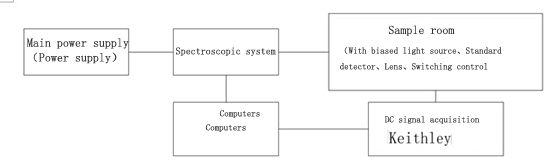

According to the basic principle of dye sensitized cell, dye sensitized cell needs to go through a series of oxidation-reduction reactions to realize the conversion of light into electricity. The oxidation-reduction reaction of dyestuff in a dye-sensitized cell is composed of a series of complex reactions, and the oxidation-reduction rate directly affects the stability, conversion efficiency and response speed of the cell. The oxidation-reduction rate is influenced by various factors such as dye type, dye concentration, electrolyte type, and electrolyte ion diffusion rate. In general, the time required to form a stable conversion system is in the order of "seconds", which means that the response speed of dye-sensitized cells is relatively slow, and if modulated AC test mode is used, the frequency needs to be lower than 1Hz, which is difficult to achieve in practice. Therefore, the DC test mode is more suitable for IPCE testing of dye-sensitized cells.

IPCE testing differs from I-V testing in that a monochromatic light is shone on the surface of the cell and the intensity of that monochromatic light has to be accurately measured. Therefore, in the IPCE test, a standard device that can be calibrated for light intensity is required, and the intensity of the monochromatic light shining on the standard device and the sample under test should be the same. Therefore, during the test, the spot of monochromatic light should be smaller than the effective area of both the standard device and the sample under test to ensure the accuracy of the test results. The structural characteristics of the dye-sensitized cell determine that only the area under the light produces the sensitization reaction, while the conductive band and electrolyte are completely distributed over the entire effective area of the cell, thus increasing the chance of the electrons being compounded, which leads to the lower output current of the cell.

In order to ensure the accuracy of IPCE test, all effective areas of the battery should be in working condition during the test to reduce the occurrence of "internal consumption", and the most effective way is to add bias light to the battery during the measurement. Referring to the relevant domestic and international standards and testing experience, it is determined that the intensity of bias light is most suitable at a level of about 0.5 SUN (AM1.5).

Trial cells: dye-sensitized solar cells, chalcogenide cells or other single-junction solar cells that can be tested by the DC method, and related semiconductor materials tested by the DC method.

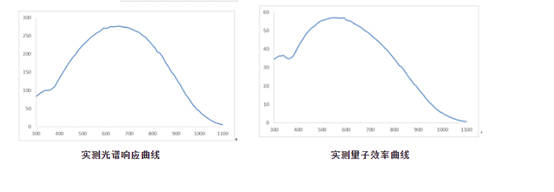

Test data: absolute spectral response, quantum efficiency or photoelectric conversion efficiency IPCE and standard solar AM1.5G, short-circuit current density

1)Conform to ASTM E1021-12, IEC60904-8, GB/T6495.8-2002 and other domestic and international latest test standards.

2)"One key" fully automatic test, automatically switch between standard and tested parts, the test process does not require any manual participation.

(3) High stability, high power, long life continuous monochromatic lighting, to ensure accuracy and repeatability.

4) High-stability, long-life continuous white light bias to ensure accuracy and repeatability.

5) Spectroscopic system to ensure good wavelength accuracy and repeatability, eliminating the influence of multi-level spectrum and small stray light.

6)The sample chamber adopts total reflection type optical path to avoid multiple reflections of the transmitting elements causing inaccurate testing.

(7) Adopt American Keithley digital meter to ensure the accuracy of signal testing and high acquisition speed.

Main technical specifications.

Indicators | Parameters |

Applicable batteries | Dye sensitized solar cells, chalcogenide cells or other single junction solar cells that can be tested by DC method, and related semiconductor materials that can be tested by DC method |

Control mode | Software control, fully automatic scanning, automatic error elimination, automatic background deduction |

Spectral range | 200-1100nm |

Scan interval | ≥1nm continuously adjustable |

Spectral scan | Fully automatic, continuous |

Repeatability of test results | <0.3% (short-circuit current) |

Operating mode | DC mode DC |

Chopper frequency | 5-1000Hz |

Temperature control table. | Temperature control range 5-40 ℃ (±0.5 ℃), optional |

Bias light source | Standard 1 way, imported white light / xenon lamp |

Monochromator | Focal length 300mm, 150mm optional |